If it wasn’t essential to have the details of the fibers and wood grain visible, we could just paint the wood.

We want the ebonizing process to meld with the grain and fibers of the wood and make the wood appear as if it is black from the fibers up. The reason to stop at 220 is higher grit sandpapers will potentially burnish the wood surface and make it more difficult for the ebonizing processes to penetrate the surface. Sand the wood surface up to, but not past 220 grit sandpaper. If you are turning a bowl, the surface needs to be completely turned and sanded. The surface of the wood needs to be prepared for the process. In addition, we will cover additional ebonizing techniques that will work for most any species of wood. Woods with lower tannin content will not respond well to the iron acetate process, but we can encourage them to be more responsive. Some woods that contain higher amounts of tannin include oaks, cherry, and walnut. However, if we only use the iron acetate method, which we will discuss more in a minute, we need wood with a high tannin content to achieve a rich black color. Best Woods To EbonizeĪny wood can be ebonized and made to look black. However, ebonizing wood is affordable and much more practical. Yes, ebonized wood is not the same quality or density as genuine ebony. To achieve the look of ebony, we can colorize a lesser expensive and more available wood to make it appear jet black like ebony. Ebony is rare, not easily accessible, and very expensive. A single board foot of ebony (12″ x 12″ x 1″ or equivalent size) can weigh over 5 lbs. If that wasn’t enough, shipping ebony around the world is also pricey because of the wood’s weight. Depending on where you look, ebony can sell for over $100 (U.S. The high demand combined with diminishing quality makes ebony a very high priced wood to turn into shavings on the lathe. It is common to find ebony with lighter colored veins and not necessarily solid jet black in appearance. Because of its popularity, ebony is harvested heavily within its growing regions.Īlso, because of the high demand for ebony and massive production, ebony quality has diminished. The sapwood around the heartwood of the ebony is very light tan or pinkish in color.Įbony is highly prized for its characteristic solid black color and density.

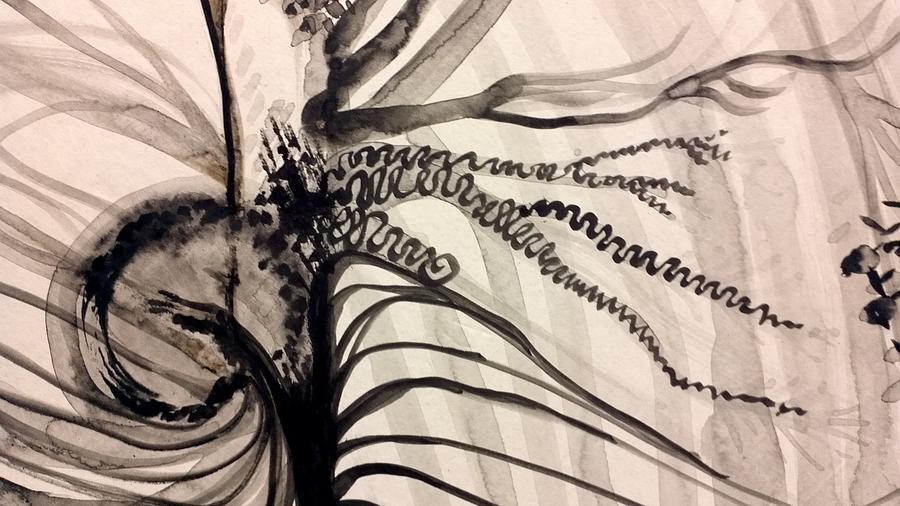

It is the heartwood of the ebony tree that contains the famous jet black dense wood fiber. Ah, I guess that’s a topic for another time.Įbony tree varieties grow in India, Africa, Madagascar, South and Central America, and Indonesia. Hm? That makes me wonder about persimmon wood. Ebony is such a dense hardwood that it will sink instead of float in water.įound in several species of the tree genus Diospyros, the ebony tree is also related to the persimmon tree. The Real ThingĮbony is a beautiful decorative and ornate wood that is very dense. While using chemicals to cause a reactive process has been a long-standing ebonizing practice, there are several other options available. Traditionally, woodworkers have ebonized wood by using a reactive chemical solution that penetrates the wood and is responsive to tannins present in the wood cells. Ebonized wood can be created with a chemically reactive process or other means to color the wood black, like ebony, while still allowing the wood grain to show through. But before we go further, there is a question that needs to be asked.Įbonizing wood is the effect of darkening or blackening a naturally lighter colored wood to appear more like black ebony wood. With this tile, you know what you will get, and for a restaurant or bathroom application it is perfect because it is easy to clean.Ebonizing wood has been around for a very long time. (6″x36″ could border a large field of 18″x36″ or the have a grouping of 6″x36″ in herringbone pattern create a path through the 18″x36″ field.) Another unique element to the collection is the Wood colorway – perfect if you’re looking to cover a wall with a reclaimed wood aesthetic but don’t want to deal with the cumbersome nature of reclaimed wood. The range of sizes also allows you to create color on color patterns with the 6″x36″ and 18″x36″. This collection can work with many applications including lobbies, kitchens, bathrooms – you name it. There is also a great deal of depth in the color palette White has subtle grey tones mixed in with it to create dimension, Dark’s cool black tones are balanced with the softness of chocolate browns. As you look closely at the various colorways, there is the subtle detailing of wood grain, reminiscent of a more prominent board-formed aesthetic. At first glance, Iron Wood may appear like just another concrete look, however it’s so much more! Iron Wood combines the aesthetics of concrete, metal and wood, then antiques the finish, giving the impression they’ve been worn over time.

0 kommentar(er)

0 kommentar(er)